Qed reference XT 3 da 1 metro cavo di alimentazione Qed

€ 79,00 € 39,50

QED XT3 power cable EU

QED is proud to introduce XT3 power cable, the latest in a new generation of audiophile power cables intended to complement its award-winning range of speaker cables and audio interconnects.

QED is proud to introduce XT3 power cable, the latest in a new generation of audiophile power cables intended to complement its award-winning range of speaker cables and audio interconnects. Having introduced some of the very first specialist speaker cables and with over 47 years of unrivalled engineering excellence in the field of audio-visual connectivity, no other company can demonstrate such relentless dedication to research and development combined with analytical listening tests.

The new cord set features a number of proprietary technologies applied with regard to objective scientific research and subjective evaluation, to bring an audible improvement in performance.

As a result of X-Tube™ technology being applied to the XT3 power cable, fewer distortions caused by modulation of the impedance of the cable will affect current flow to audio equipment and so are less likely to find their way into the music.

Without a cable such as this to supply clean, noise-free current, many amplifiers can sound glassy and hard with less ability to respond to musical transients, giving a lack of dynamics and weak bass performance.

Finally, with the quality assurance of a fully typetested design, XT3 can be relied upon to safely bring audible improvements to audiophile source and amplification components alike.

QED XT3 power cable EU

FEATURES AND BENEFITS

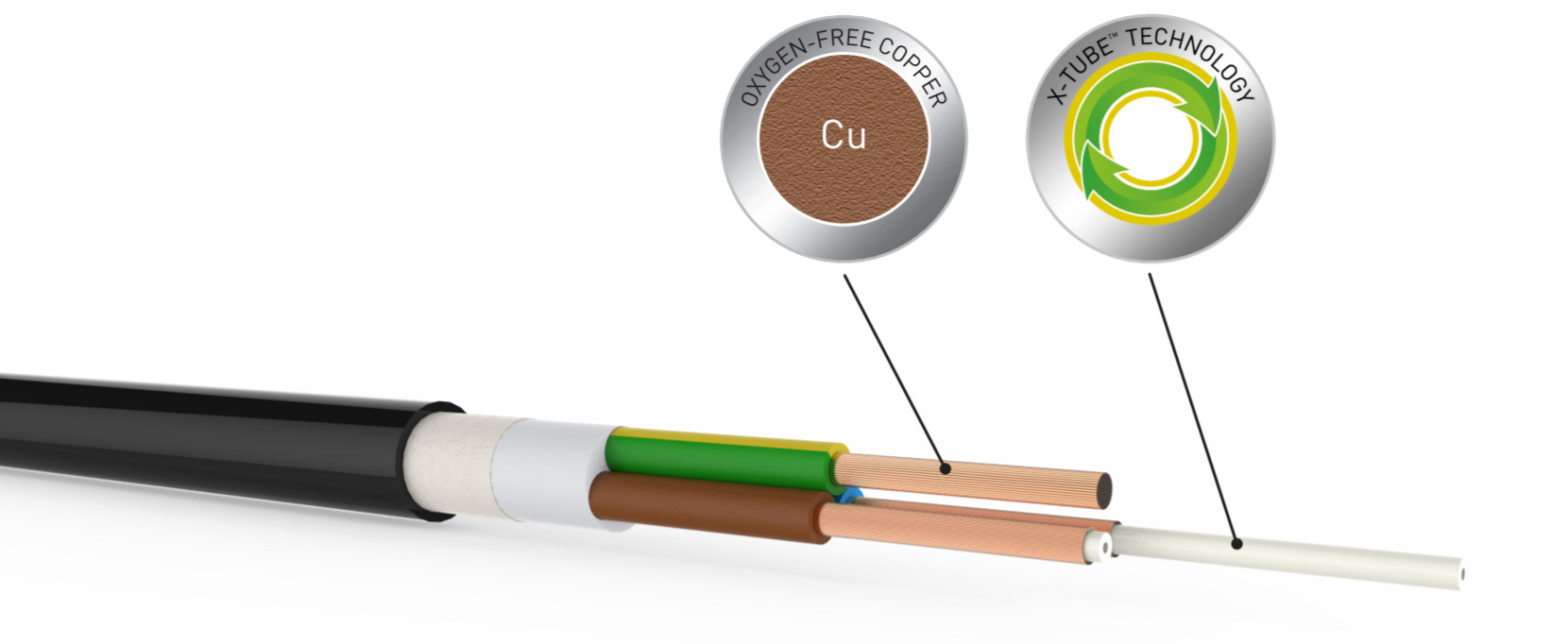

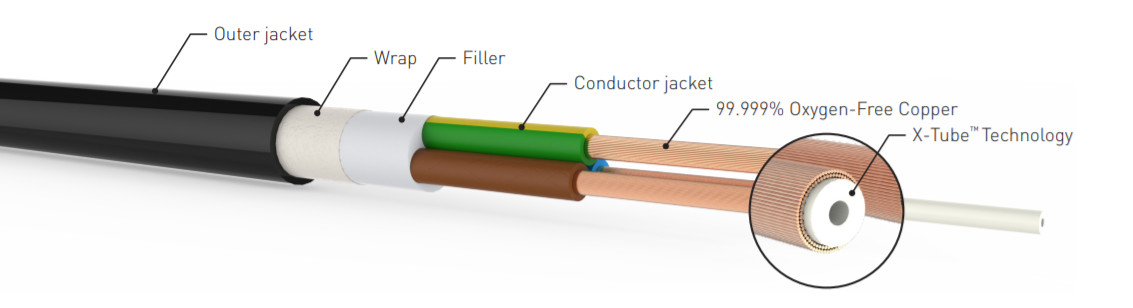

X-Tube technology

QED XT3 power cables feature a specially adapted version of X-Tube™ Technology similar to that used in our speaker cables but specifically tuned to be appropriate for this new application. The braided individual cores in the live and neutral conductors are made small enough that they are not affected by the eddy currents from adjacent cores which help contribute to the proximity effect.

Because they are effectively isolated from one another the carefully calculated twist rate of the strands means that no two conductors remain next to each other in the parallel configuration for more than a few millimetres, further enhancing the even current flow along the cable at all frequencies. The separate bundles are individually insulated using K130 PVC to control cable capacitance and provide the level of electrical isolation demanded by international safety standards, the whole arrangement is provided with a hollow LDPE core to control cable inductance. In this way the correct phase relationship between voltage and current is not altered by the cable parameters, further decreasing distortion when compared to an ordinary power cable.

Complete practicality

XT3 is designed to be as thin and flexible, and thus practical, as possible. Only the live and neutral cores have been given the X-Tube treatment described above – the earth core (required only under fault conditions) is left in a conventional geometry. And because X-Tube geometry enables the whole cross-sectional area of the cable to be kept to a tidy 1.5 mm sq, XT3 is supremely flexible and usefully slim despite its audiophile potential.

Specifications

- Conductor type: X-Tube

- Metallurgy: 99.999% oxygen-free copper

- Cross-sectional area: 1.5 mm sq

- Capacitance: 86 pF/m

- Inductance: 0.50 μH/m

- Loop resistance: 0.026 ohm/m

- Dielectric strength: 2 kV (ac for 15 mins)

- Complies with: EN50525; EN60320; EN60884

- Outer jacket: Black Pearl

- Nominal outside diameter: 10.2 mm

- Plugs: CEE 7/7

- Connector: IEC C13 794

QED XT3 safety & type testing

There are many alternative brands of audiophile mains products on the market but even a cursory investigation reveals that many do not have the full set of required safety test reports and type testing certificates demanded by international legislation.

Rest assured, this is not the case with QED power cables. Because of the constraints which we placed on the design, the cordage fits into standard, high-quality plugs and connectors which fall into the parameters described by the harmonised standards.

In addition, the completed cord set including any additional overmould, covers and branded strain relief items added by us have been fully type tested to EN 60320, EN 60884 & EN 50525 by an accredited certification body and found to be fully compliant. Regular testing of the product at our production facility as set out in the annex to these standards is also carried out. A full test report is available on request from [email protected].

Because mains plugs and connectors are not generally supplied as standard with gold plated pins, any that you might see for sale have usually been variously modified after manufacture by the reseller. This is not a good idea, as any type-testing certification which might be available for the product will have been invalidated by this process; effectively a new “type” has been created which is not the subject of the test report.

Spedizione veloce e imballaggio professionale

A causa delle nostre relazioni di lunga data con UPS FedEx DHL e altri migliori vettori internazionali, siamo in grado di fornire varie opzioni di spedizione. Il nostro personale di magazzino è altamente addestrato per impacchettare le tue merci esattamente in base alle specifiche che forniamo. Prima della spedizione, tutte le merci verranno esaminate accuratamente e sicure in modo sicuro. Forniamo a migliaia di clienti ogni giorno in diversi paesi. Questo è un segno del nostro impegno per essere il più grande rivenditore online in tutto il mondo. I magazzini e i centri per la distribuzione sono in Europa e negli Stati Uniti.

Nota: gli ordini che contengono più di un articolo viene assegnato un periodo di elaborazione secondo l'articolo.

Prima di spedire gli articoli, il nostro personale effettuerà un'ispezione approfondita sugli articoli acquistati. La maggior parte degli ordini viene consegnata entro 48 ore. Il tempo di consegna varia da 3-7 giorni.

ritorna

Lo stock è dinamico e non possiamo gestirlo completamente a causa del fatto che sono coinvolte più parti, che include la nostra fabbrica e il nostro magazzino. I livelli di stock effettivi possono fluttuare in qualsiasi momento. È possibile che non riceverai il tuo ordine una volta che è stato effettuato.

La nostra politica dura trenta giorni. Se 30 giorni sono andati senza traccia dall'acquisto, tuttavia, non siamo in grado di darti un rimborso o uno scambio.

Puoi restituire un articolo solo nel caso in cui non sia usato e ancora nelle stesse condizioni quando lo hai ricevuto per la prima volta. L'articolo deve essere restituito nella confezione originale.

Prodotti correlati

Cavi di alimentazione

Supra LoRad 1.5 MKII CS EU terminato IEC e SCHUKO cavo di alimentazione di qualità Supra Cables

Cavi di alimentazione

Ifi Supanova Eu cavo di alimentazione da 1.8mt Hi-End con sistema attivo di cancellazione rumore Ifi

Cavi di alimentazione

Isotek EVO3 Syncro Uni Dispositivo di blocco corrente continua attivo Isotek

Cavi di alimentazione

Ifi Quasar cavo di alimentazione con geometria bilanciata Ifi

Cavi di alimentazione

Ifi iPOWER ELITE 12V 4A Trasformatore audiofilo con noise cancellation Ifi

Cavi di alimentazione

Isotek V5 GEMINI Distributore di alimentazione a 2 prese individuali Isotek

Cavi di alimentazione

Cavi di alimentazione

Supra MD-06 EU/SP MKIII switch multipresa a 6 Schuko con interruttore Supra Cables

cavi altoparlanti a metraggio

Qed Golden Anniversary XT cavo per diffusori prezzo al metro Qed

Cavi di alimentazione

Audioquest NRG-Z3 da 2 MT cavo di alimentazione impedenza ZERO rame PSC Audioquest

Cavi di alimentazione

Ifi AC iPurifier purificatore attivo delle reti elettriche Ifi

Cavi di alimentazione

Isotek EVO3 Optimum da 2MT Cavo di alimentazione in rame O.C.C. placcato argento Isotek

Cavi di alimentazione

Wireworld STRATUS 7 (elp) cavo alimentazione in rame OFC da 1 MT terminato schuko WIREWORLD

Kit cavi completi

Audiosystem AD35B/B cavo alimentazione da 35mmq in puro rame 100% prezzo al ML Audiosystem

Cavi di alimentazione

Isotek V5 Corvus Distributore di alimentazione a 9 prese individuali Isotek

Cavi di alimentazione

Cavi di alimentazione

Audioquest NRG-Z3 da 1MT cavo di alimentazione impedenza ZERO rame PSC Audioquest

Cavi di alimentazione

Wireworld STRATUS 7 (elp) cavo alimentazione in rame OFC da 1,5 MT terminato schuko WIREWORLD

Cavi di alimentazione

Supra LoRad 2.5 mkII angled terminato IEC e SCHUKO cavo di alimentazione di qualità Supra Cables

Cavi di alimentazione

Ifi iPOWER ELITE 24V 2.5A Trasformatore audiofilo con noise cancellation Ifi

Cavi di alimentazione

Isotek EVO3 Elite da 2MT Cavo di alimentazione in rame puro O.F.C. 6N placcato argento Isotek

Cavi di alimentazione

Isotek EVO3 Premier cavo di alimentazione da 1.5mt rame puro O.F.C. 6N placcato argento Isotek

Cavi di alimentazione

Ifi iPOWER ELITE 5V 5A Trasformatore audiofilo con noise cancellation Ifi

Cavi di alimentazione

Ifi Nova Eu cavo di alimentazione da 1.8mt realizzato in rame OFHC Ifi

Cavi di alimentazione

Supra LoRad 2.5 mkII terminato IEC e SCHUKO cavo di alimentazione di qualità Supra Cables

Cavi di alimentazione

Isotek V5 ACQUARIUS Distributore di alimentazione a 6 prese individuali Isotek